CONTACT

Tel/Fax: +86-18858689791

E-mail: Shengkun.liuxu@gmail.com

WhatsApp: +8618858689791

Address: Luqiao Sub - district, Luqiao District, Taizhou City, Zhejiang Province

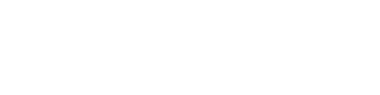

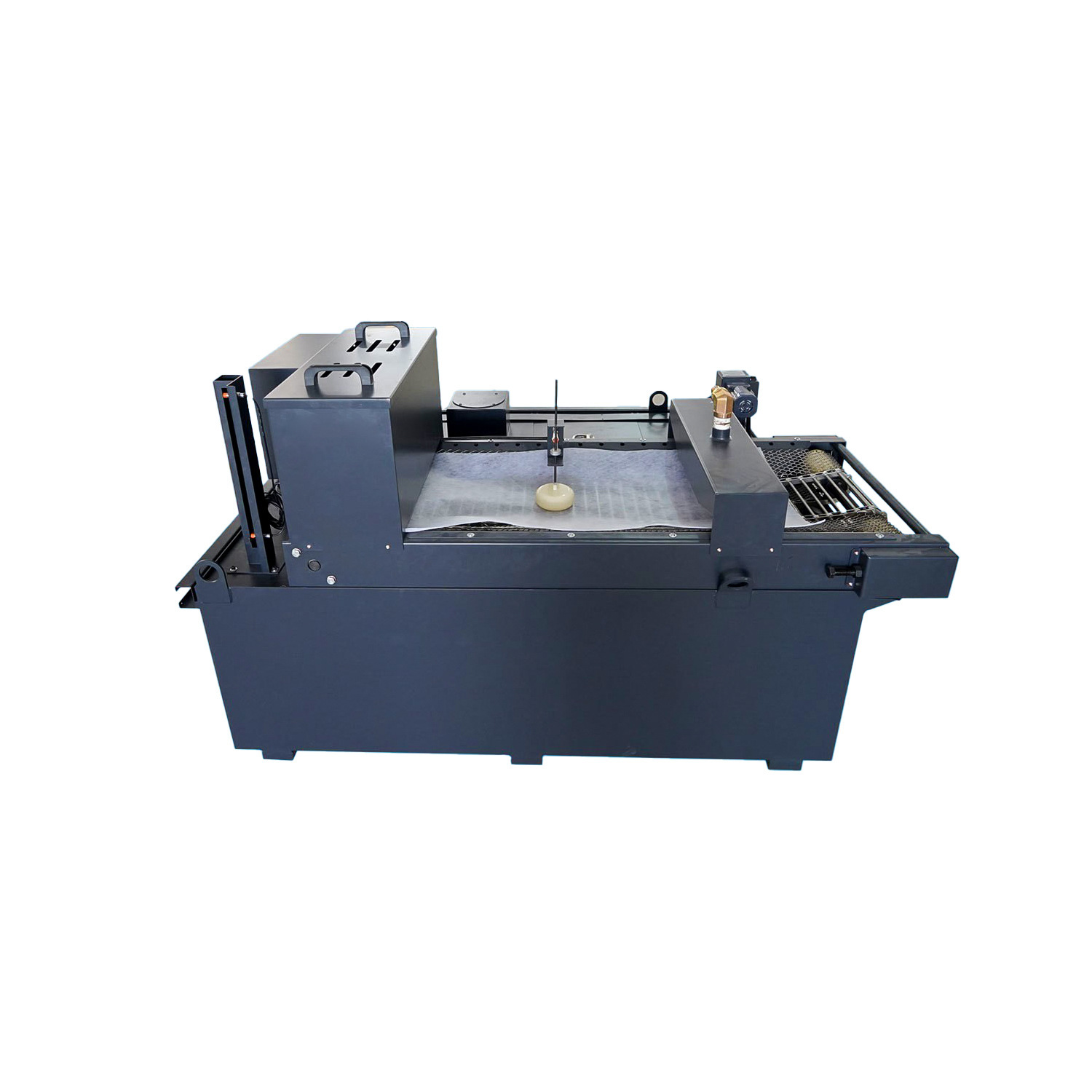

SKT-CC-009 Centralised chip conveyor unit

Our main products include various types of roll forming machine, pipe processing machine, wire drawing machine, lathe and other related machines, etc.

- Commodity name: SKT-CC-009 Centralised chip conveyor unit

Technical documentation

The centralised chip conveyor device is a combination of large-scale chip conveyor, which generally adopts chain plate chip conveyor and chain dragging to scrape out the chips along the bottom of the chip conveyor, so as to collect and convey granular metal iron chips, fine iron chips, casting iron chips and non-metallic chips, with a large conveying flow. The machine has streamline modelling, beautiful appearance, smooth chip removal, small volume, high efficiency, stable transport, safe and reliable, low noise, and overload protection function. The pitch is 31.75mm and 50.8mm for choice.

The process of machining and manufacturing will produce a large number of chips. These chips often contain a large amount of oil and cutting emulsion. Due to the fluffy chips, easy to scatter around the machine tool and the workshop channel, so it is not only difficult to clean up, but also seriously pollute the workshop environment. The traditional solution is to clean up the chips manually and finally converge the chips into a large chip box, which is regularly lifted to the car by an overhead crane and transported out. This method is a large workload, waste of manpower, and occupy the production overhead crane, easy to conflict with the production, and the workshop chip storage area will take up the effective use of the workshop area, affecting the logistics of the workshop, but also cause difficulties in the management. With the development of the production of CNC machine tools are widely used, the workpiece processing efficiency has been greatly improved, but the corresponding research for the machine tool chip removal is relatively lagging behind, and now most of the research on chip removal is only for a single machine tool, rarely involved in the design of the entire workshop chip removal system. For this reason, our company designs a set of solutions for the whole workshop chip removal system.

- 产品描述

-

The centralised chip conveyor device is a combination of large-scale chip conveyor, which generally adopts chain plate chip conveyor and chain dragging to scrape out the chips along the bottom of the chip conveyor, so as to collect and convey granular metal iron chips, fine iron chips, casting iron chips and non-metallic chips, with a large conveying flow. The machine has streamline modelling, beautiful appearance, smooth chip removal, small volume, high efficiency, stable transport, safe and reliable, low noise, and overload protection function. The pitch is 31.75mm and 50.8mm for choice.

The process of machining and manufacturing will produce a large number of chips. These chips often contain a large amount of oil and cutting emulsion. Due to the fluffy chips, easy to scatter around the machine tool and the workshop channel, so it is not only difficult to clean up, but also seriously pollute the workshop environment. The traditional solution is to clean up the chips manually and finally converge the chips into a large chip box, which is regularly lifted to the car by an overhead crane and transported out. This method is a large workload, waste of manpower, and occupy the production overhead crane, easy to conflict with the production, and the workshop chip storage area will take up the effective use of the workshop area, affecting the logistics of the workshop, but also cause difficulties in the management. With the development of the production of CNC machine tools are widely used, the workpiece processing efficiency has been greatly improved, but the corresponding research for the machine tool chip removal is relatively lagging behind, and now most of the research on chip removal is only for a single machine tool, rarely involved in the design of the entire workshop chip removal system. For this reason, our company designs a set of solutions for the whole workshop chip removal system.

Centralised chip conveyor device features:

1、It can deal with all kinds of chips; it can also be used as the conveying device for small parts of stamping and cold pier machine tools.

2、High conveying efficiency and wide range of conveying speed selection;

3、Diversified width of chain plate.

4, streamline modelling, beautiful and generous, smooth chip discharge.

5、With overload protection function.

6、High degree of product serialisation and standardisation, simple operation, reliable operation and easy maintenance.

The centralised chip conveyor device is widely used in the chip conveying of CNC machine tools, combined machine tools, machining centres, specialized machine tools, assembly lines, automatic lines, etc., and the chip conveying of large-scale machine tools and production lines over long distances.

Advantages of centralised chip conveyor device:

1、Coolant management is easy, only one main oil tank can be regularly checked by a special engineering staff Concentration, acidity and alkalinity, bacteria number to keep the quality of coolant stable.

2, the filtration host filtration precision is higher and not too much dead space, so that the sludge deposited to reduce the bacteria are less likely to breed.

3、The life span of coolant can be effectively extended and the environmental protection problem of coolant pumping can be reduced.

4、The recovery rate of chips (aluminium alloy) is high to reduce the loss of materials.

5、Chips and coolant flow back to the filtering host together, without additional manpower to carry aluminium chips in the factory.

6、Long-term running cost is low and has the peripheral equipment of environmental protection.

Keywords:

Drag Chain,Chip Conveyor

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

HZ.101012 Milling machine handwheels

Color: Photo Black Material: Phenolic resin(bakelite) Usage: Suitable for vertical milling, universal milling special the handwheel

SKT-OS-005 Inclined Paper Tape Filter

Inclined paper belt filter consists of filter box, paper belt, inclined plate

SKT-OS-004 Grinding Machine Automatic Paper Tape Filter Machine

Flat mesh magnetic roller paper belt filter consists of liquid tank

SKT-OS-003 Flat Mesh Magnetic Roller Paper Tape Filter

Flat mesh magnetic roller paper belt filter consists of liquid tank