CONTACT

Tel/Fax: +86-18858689791

E-mail: Shengkun.liuxu@gmail.com

WhatsApp: +8618858689791

Address: Luqiao Sub - district, Luqiao District, Taizhou City, Zhejiang Province

SKT-KS-001 Flexible Armor Shield

Our main products include various types of roll forming machine, pipe processing machine, wire drawing machine, lathe and other related machines, etc.

- Commodity name: SKT-KS-001 Flexible Armor Shield

Technical documentation

The centralised chip conveyor device is a combination of large-scale chip conveyor, which generally adopts chain plate chip conveyor and chain dragging to scrape out the chips along the bottom of the chip conveyor, so as to collect and convey granular metal iron chips, fine iron chips, casting iron chips and non-metallic chips, with a large conveying flow. The machine has streamline modelling, beautiful appearance, smooth chip removal, small volume, high efficiency, stable transport, safe and reliable, low noise, and overload protection function. The pitch is 31.75mm and 50.8mm for choice.

The process of machining and manufacturing will produce a large number of chips. These chips often contain a large amount of oil and cutting emulsion. Due to the fluffy chips, easy to scatter around the machine tool and the workshop channel, so it is not only difficult to clean up, but also seriously pollute the workshop environment. The traditional solution is to clean up the chips manually and finally converge the chips into a large chip box, which is regularly lifted to the car by an overhead crane and transported out. This method is a large workload, waste of manpower, and occupy the production overhead crane, easy to conflict with the production, and the workshop chip storage area will take up the effective use of the workshop area, affecting the logistics of the workshop, but also cause difficulties in the management. With the development of the production of CNC machine tools are widely used, the workpiece processing efficiency has been greatly improved, but the corresponding research for the machine tool chip removal is relatively lagging behind, and now most of the research on chip removal is only for a single machine tool, rarely involved in the design of the entire workshop chip removal system. For this reason, our company designs a set of solutions for the whole workshop chip removal system.

- 产品描述

-

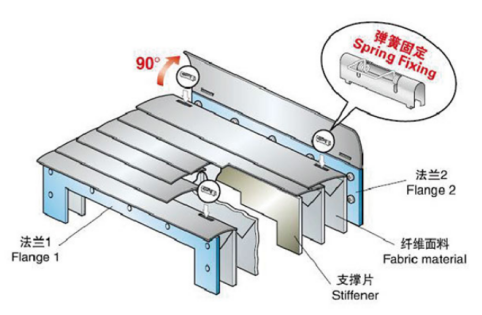

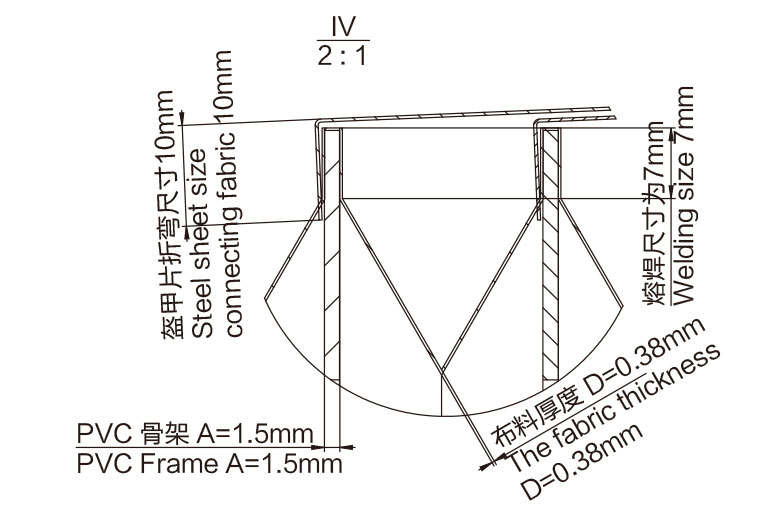

Each folded layer of the armoured shield can withstand strong vibration without deformation, while applied to the wind box to 900 ℃ high temperature and still maintain the original state, they support each other and play a role in hindering the penetration of small fragments.

※Pressing the expansion piece on the shroud lattice

※Small space requirement

※Reliable protection against large amounts of dust, sand, and iron filings and high temperatures.

※The telescopic sheet is made of aluminium alloy and stainless steel plate.

※No bondingFeatures of armored protective cover

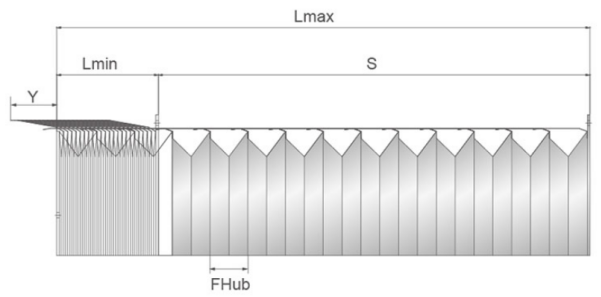

In the technical design of the armor skin cavity protective cover for the fixed armor piece, the space occupied by the shrinking armor piece after extending out of the skin cavity must be considered (the Y size shown in the figure below). The movable armor piece series can evade this.

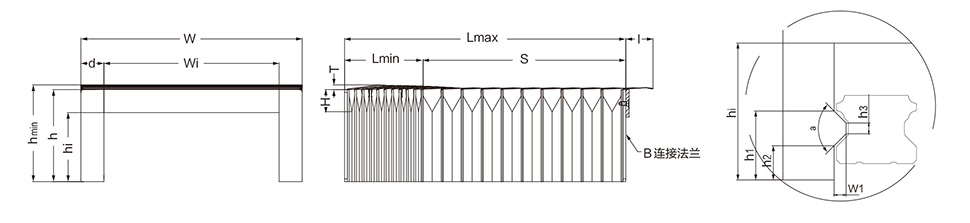

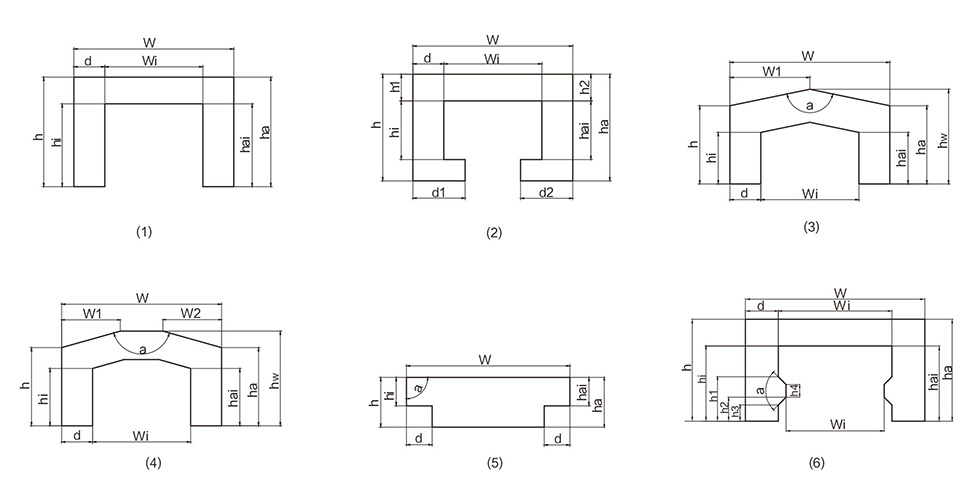

Schematic diagram of the technical parameters of the armor shield

K is the snap of the armour piece, which must be cross-assembled when there is not enough space for expansion and contraction

T is the thickness of the armour piece after compression of the shield

-Lmax=maximum stretch of the shield

-Lmin = minimum compression of the shield

-S=Stroke length

-W = outer width of the shield

-Wi=Width inside the shield

-h=Height outside the shield

-hi=Inside height of shield

-H=Holding height

-n=number of folds of the shield

-D = Fabric of the shield

-A=Skeleton of shield

-B = flanges at both ends of the shieldH≤h-hi or H≤(W-Wi)/2 (symmetrical on both sides); if there is no special instruction, the flanges at both ends of the shield are made of Q235, and the armour piece is SUS304

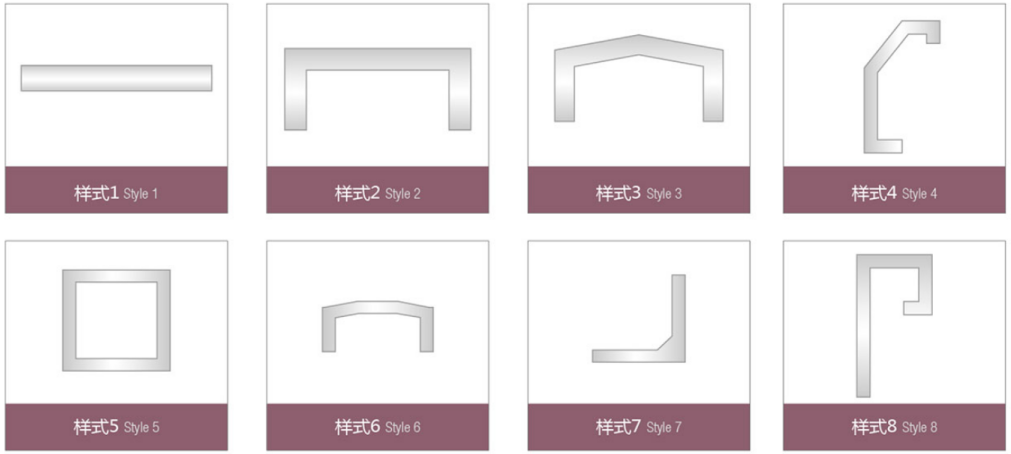

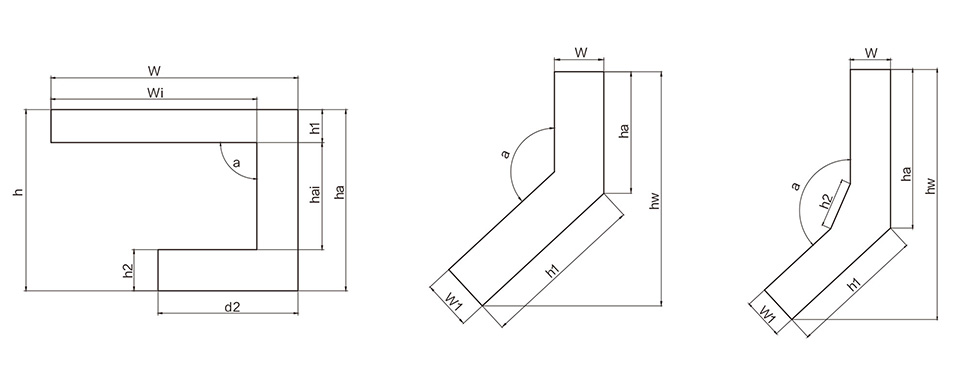

Shape Of Armor Type Protective Cover

Technical Description

S=Stroke

FHub=Single folding stroke

Lmax=Maximum stretch

Lmin=Minimum compression

Lmax/Lmin/H

15

20

25

30

35

40

100

56

31

26

21

16

16

150

81

46

31

26

21

21

200

106

56

41

31

26

26

250

131

71

51

41

31

31

300

156

81

56

46

36

31

350

181

96

66

51

41

36

400

206

106

76

56

46

41

450

231

121

81

61

51

46

500

256

131

91

71

56

51

550

281

146

101

76

61

56

600

306

156

106

81

66

61

650

331

171

116

91

71

66

700

356

181

126

96

76

71

750

381

206

141

101

81

76

800

406

216

146

106

86

81

850

431

231

156

111

91

86

900

456

246

166

116

96

91

950

481

256

171

121

101

96

1000

506

271

181

131

106

101

1500

-

-

256

196

156

131

2000

-

-

341

256

206

176

2500

-

-

426

321

256

216

3000

-

-

506

381

306

256

3500

-

-

591

446

356

296

4000

-

-

676

506

406

336

4500

-

-

756

571

456

376

5000

-

-

841

631

506

416

Flexible armoured shields

Shaped shields

Shield parameters

Keywords:

Drag Chain,Chip Conveyor

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products

HZ.101012 Milling machine handwheels

Color: Photo Black Material: Phenolic resin(bakelite) Usage: Suitable for vertical milling, universal milling special the handwheel

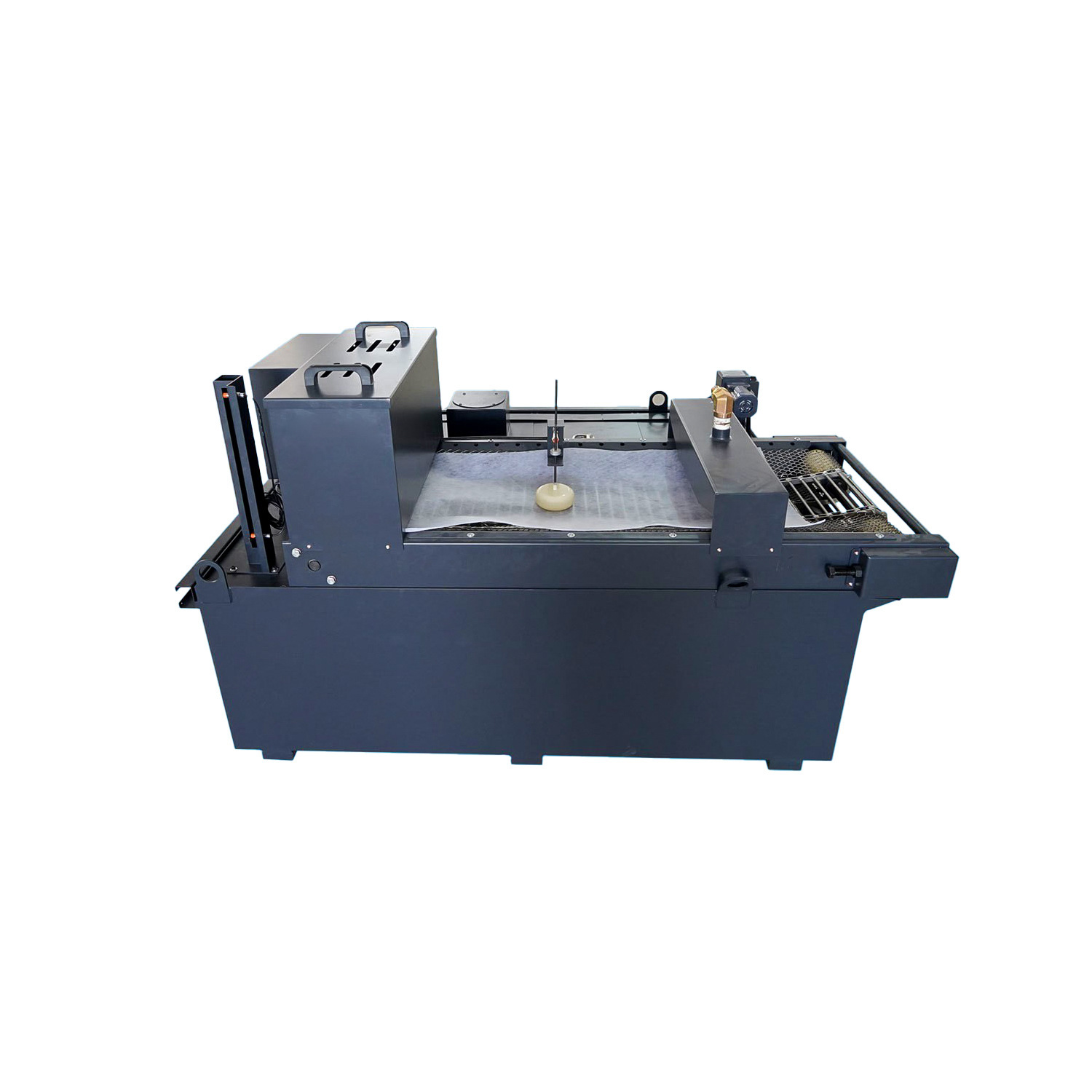

SKT-OS-005 Inclined Paper Tape Filter

Inclined paper belt filter consists of filter box, paper belt, inclined plate

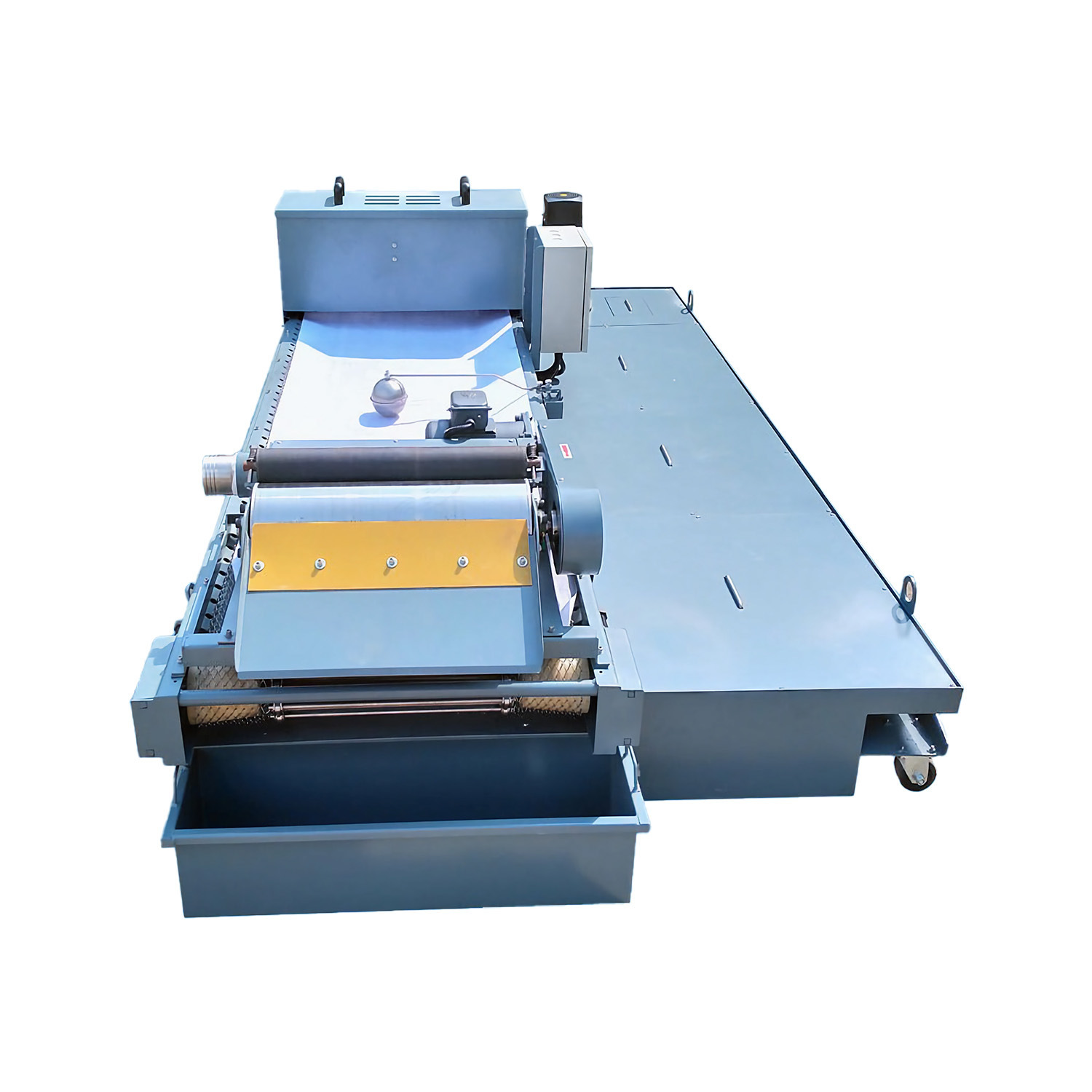

SKT-OS-004 Grinding Machine Automatic Paper Tape Filter Machine

Flat mesh magnetic roller paper belt filter consists of liquid tank

SKT-OS-003 Flat Mesh Magnetic Roller Paper Tape Filter

Flat mesh magnetic roller paper belt filter consists of liquid tank